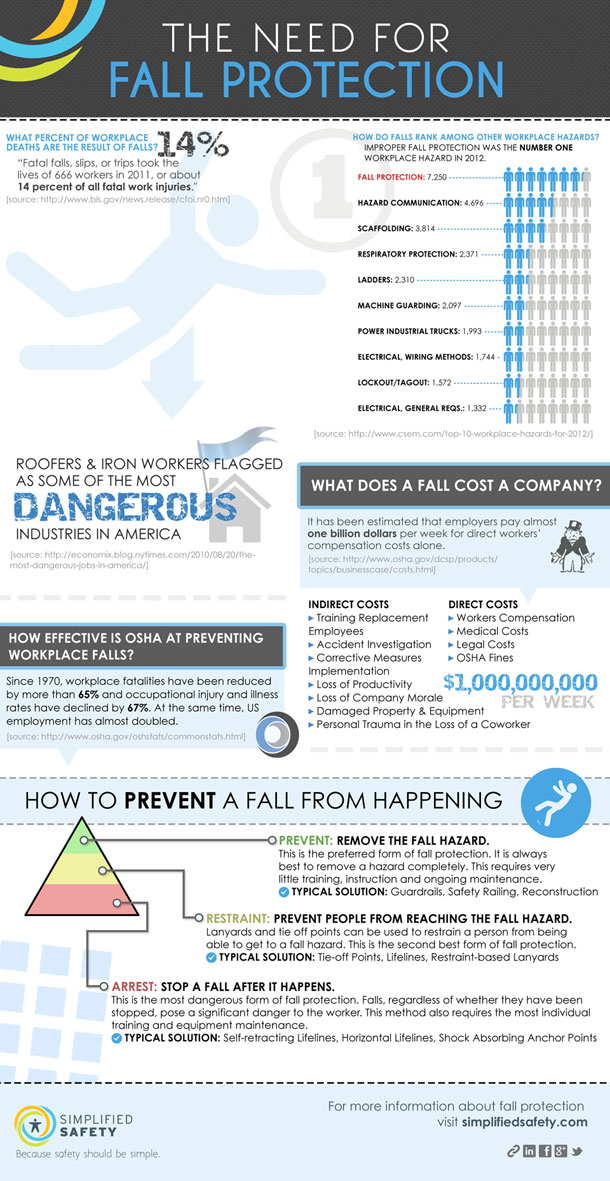

Courtesy of: Simplified Safety - Fall Protection Products & Solutions

Practical Workplace Safety Discussions You Can Use!

Storage shall be prohibited except that which is required for maintenance and operation of building and operation of equipment. Such storage shall be kept in closed metal containers stored in a storage cabinet or in safety cans or in an inside storage room not having a door that opens into that portion of the building used by the public.While this discussion centers on OSHA regulation, NFPA 30 also has a lot to say about the use of storage rooms/cabinets, ignition source control (50 feet) and management of other hazards for flammable storage. A fire could result in both OSHA and Fire Marshal inspections.

"At least one portable fire extinguisher having a rating of not less than 12-B units shall be located outside of, but not more than 10 feet from, the door opening into any room used for storage."

"Open flames and smoking shall not be permitted in flammable liquid storage areas."

(2005-) The Office, Episode: “Boys and Girls”, warehouse scene. CLIP ENDS AT 00:24

Aisles shall be maintained to retard the transfer of fire from one pile to another and to permit convenient access for fire fighting, salvage, and removal of storage.

"Stunt driving and horseplay shall not be permitted."

Each employee shall comply with the standards, rules, regulations and orders issued by his/her agency in accordance with section 19 of the Act, Executive Order 12196, and this part which are applicable to his/her own actions and conduct.

The employer shall ensure that each powered industrial truck operator is competent to operate a powered industrial truck safely, as demonstrated by the successful completion of the training and evaluation specified in this paragraph (l).

When a forklift is left unattended, load engaging means shall be fully lowered, controls shall be neutralized, power shall be shut off, and brakes set. If the forklift is only dismounted (operator within 25’ and within line-of-sight) the truck need-not be shut-off.Reprinted by Invitation from Compliance and Safety - We enjoy their work here at SaferWorkSite

Like this Blog Entry - Learn More Here: http://complianceandsafety.com/blog/oshavshollywood/

|

Classroom for on the job safety training, at Reditus

|

General Information

|

Permit #

|

Name of Scaffold Erector:

|

Installation Date:

Expiration:

|

Renter Name:

|

Phone #

|

Shed Type: Light [ ] Med [ ] Heavy [ ] Duty

|

Are Drawings on Jobsite for Inspection

Yes [ ] No [ ]

|

Specific Information:

|

Scaffold Height:

|

Number of Platforms Decked:

|

Base Plates and Mudsills Secured?

Yes [ ] No [ ]

|

Are the Signs on the Parapets?

Yes [ ] No [ ]

|

Are all Scaffold Pins and Bolts installed?

Yes [ ] No [ ]

|

Maintenance Information

|

Are Legs and Poles Plumb, Braced & Not Displaced? Yes [ ] No [ ]

|

Are Cross Braces fully attached – not distorted and not missing? Yes [ ] No [ ]

|

Tie –Ins correctly spaced, properly secured and the correct number required? Yes [ ] No [ ]

|

Are Pipe Clamps Tight? Yes [ ] No [ ]

|

Are Window Jacks Tight? Yes [ ] No [ ]

|

Are all the Planks secured?

Yes [ ] No [ ]

|

Are Decking and Planks in Good Condition?

Yes [ ] No [ ]

|

Is the Deck Fully Planked?

Yes [ ] No [ ]

|

Are there Gaps or Open Spaces on Decking?

Yes [ ] No [ ]

|

Are Guardrails and Toe Boards Secured at all places as required?

Yes [ ] No [ ]

|

Is the Netting Extension of full length & height?

Yes [ ] No [ ]

|

Is the Netting Secured?

Yes [ ] No [ ]

|

Is the parapet of proper height and secured?

Yes [ ] No [ ]

|

Are the lights working properly?

Yes [ ] No [ ]

|

Is the Deck clean and free of debris?

Yes [ ] No [ ]

|

Name:

|

Title:

|

Signature:

|

Date:

|